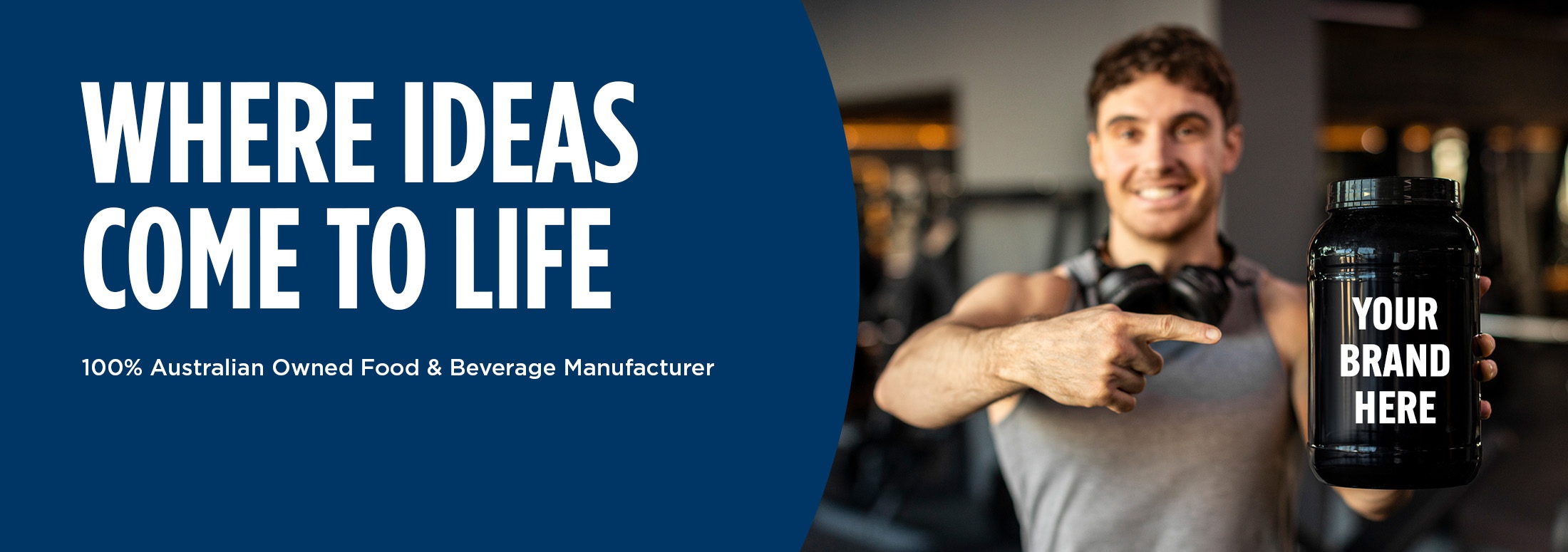

Food Manufacturing

We create, produce and deliver food products across Australia. Our company blends experience, reliable supply and packaging solutions to help brands move from idea to production with speed and consistency.

We create, produce,

& deliver products for

retail, cafes,

and foodservice.

Create: We craft liquid and powdered products for businesses of all sizes. Our liquid range includes smoothie purees, milkshake toppings, dessert sauces, flavoured syrups and natural syrups. Powdered products span sports nutrition, baking mixes, soft serve, yoghurt bases, sweeteners and hot or cold beverages. Our product development process makes it simple to develop formulas that meet your brief, required claims, and cost targets.

Produce: From formulation and packaging to production and delivery, we focus on taste, nutrition, compliance and commercial viability. Our HACCP-certified systems ensure every batch is safe, repeatable and ready for market.

Deliver: We run powdered and liquid lines in modern facilities in Victoria and Queensland. Finished goods ship wherever you need them, so you can scale without extra complexity.

Australia’s Most Trusted

Co-Manufacturing Partner

“By identifying new sales channel opportunities and leveraging best in class industry insights and product formulations, provided by the Maltra team has been pivotal in our shared successes to date.

What is food manufacturing?

Food manufacturing turns raw ingredients into consistent, safe products at scale. We plan formulations, approve suppliers, blend powders or liquids, and manage filling, sealing and coding. Each batch is checked against spec. Contract manufacturing, co-packing and OEM all describe a manufacturer producing for brands. At Maltra Foods, we specialise in powders and liquids across sports nutrition, hot beverages and cold beverages, baking mixes, soft serve, yoghurt bases and sweeteners.

-

Contract manufacturing reduces capital outlay, secures packaging options and lets you scale with confidence. A local partner brings equipment, operators, food technologists, quality systems and packaging under one roof. You focus on brand and customers while we handle production and delivery.

-

We've manufactured food and beverage products since 1997, starting with drinking chocolate and chai in St Kilda, now supplying leading retail and foodservice brands. Our HACCP-certified sites in Victoria and Queensland support development through to full production. One R&D team, one quality system, one point of contact. Fewer handovers, faster outcomes.

-

We follow a clear process to take your product from concept to production. This helps align requirements, volumes and timelines before manufacturing begins.

You provide a detailed brief and pay the development fee. The brief should include an overview of your business, marketing plans for the product, sales forecasts, key product features, claims and ingredients, packaging requirements, and any benchmark products.

Our Project Manager and R&D team review the brief and respond with questions or comments.

Upon receiving payment, we begin formulation development and provide an initial sample.

After you review and provide feedback, we create a final sample.

Once approved, we confirm final pricing and minimum order quantity.

You sign off on the quote and contract, including packaging agreements if needed.

Product is set up in our system and your product code is issued.

You place your order.

We procure materials and commence manufacturing.

-

Expect documented HACCP plans with clear critical limits, calibration, sanitation procedures and allergen control. Team members hold current food-handler qualifications and follow standard work on every line. Full traceability links each ingredient lot to finished goods.

-

Whether you need gluten-free, vegan, halal, kosher or other certifications, we plan claim requirements into the job from day one. This includes segregation, validated cleaning, supplier approval, scheduled runs and routine testing. Certificates and batch test results are available on request.

-

We support brands across retail and foodservice. Categories include hot and cold beverages, sports nutrition (powder form), dessert sauces and toppings, baking mixes, sweeteners and café solutions. This range keeps our plant flexible and helps you expand into new product ideas.

R&D Support: From Idea to Production

Our R&D team partners with you to refine flavour and nutrition, validate processes and build production-ready methods. We assist with shelf life studies, packaging trials and market samples so you can test before scaling.

PARTNER WITH A TEAM THAT CARES

ENQUIRE NOW TO GET STARTED

Food Manufacturing FAQs

-

Yes. If you have a sample or specification, our R&D team can work to match or improve the formulation for production at scale.

-

Yes. We offer end-to-end solutions including sachets, jars, film rewind and re-sealable bags, with guidance on materials, closures, coding and cartons.

-

We manufacture smoothie purees, milkshake toppings, dessert sauces, flavoured syrups and natural syrups. We do not produce ready-to-drink beverages such as bottled juices or soft drinks.

-

Minimum order quantities vary depending on the product type, format and packaging. Share your brief with us and we'll confirm suitable volumes for launch and ongoing supply.

-

We manufacture sports nutrition powders, baking mixes, soft serve bases, yoghurt bases, sweeteners and hot or cold beverage powders. Supplements are produced in powder form only.

-

Timelines depend on complexity. We'll outline clear timeframes at the start of your project.